H.C. Starck Solutions is a key manufacturer of molybdenum, niobium, tantalum, and tungsten metals and fabricated products. The company supplies targets for thin film coatings applications with an extensive vertically integrated supply chain. These products are ideal for conducting layer and barrier layer deposition in touch screen and flat panel display manufacturing.

Image Credits: Rido/shutterstock.com Molybdenum Piercing Head

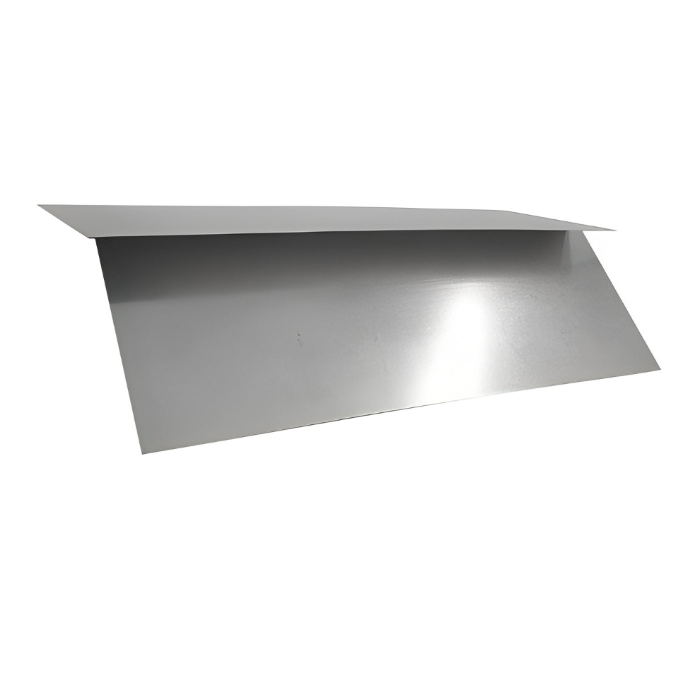

Different forms of sputtering target materials are produced at H.C. Starck Solutions’ production facilities:

H.C. Starck Solutions is focused on the research and development of thin films, making continuous investment in advanced laboratories for material processing and analysis of thin films. It has a Thin Film Materials Lab featuring planar and rotary sputtering tools and the supporting equipment such as optical and electron microscopy for characterization of thin films.

Research staff at H.C. Starck Solutions are working on the advancement of metals technology for refractory metal sputtering targets. The company has in-house prototyping, modeling and analytical capabilities to help customers and to develop new products and processes in a rapid phase. At H.C. Starck Solutions' Material Processing laboratory, evaluation targets are produced with the help of a complete chemical analysis lab.

The research and development capabilities of H.C. Starck Solutions include:

H.C. Starck Solutions' latest DynaMo product line of molybdenum-based alloys illustrates the company’s capability to provide bespoke alloys with etch characteristics, corrosion resistance, and electrical performance for higher reliability in Touch Screen Panel (TSP) applications. These alloys have large size capabilities with planar targets up to Gen 5 in size, rotary targets up to 4100mm long, and segmented (or tiled) targets.

The MoNb alloy provides higher quality films with superior corrosion resistance and fewer defects, while enabling higher sputtering rates. H.C. Starck Solutions has best-in-class extrusion process for MoNb rotary targets:

MoNb planar and rotary targets are the highest density product available in the market, enabling higher sputtering rates and higher quality film with fewer defects and superior corrosion resistance. They are used in Cu barrier and Al capping layer for TSP. H.C. Starck Solutions has in-house manufacture and control of Mo and Nb powders.

The composition and dimensions of MoNb planar and rotary targets include:

H.C. Starck Solutions supplies MoW planar targets in different compositions and dimensions:

MoW planar targets are used in gate and touch sensor layers for LTPS and in-cell type touch panels.

Image Credits: Aila images/shutterstock.com

A range of high performance, refractory metal solutions is produced by H.C. Starck Solutions for thin film sputtering applications. The company manufactures planar and rotary molybdenum (Mo) sputtering targets for thin film transistor (TFT) applications. Molybdenum thin films are used as electrodes, barrier layers, and wiring in flat panel displays (FPD) systems.

H.C. Starck Solutions’ molybdenum-tungsten (MoW) planar targets are used to form gate and touch sensor layers for TFT- LTPS and in-cell type touch panels. The largest planar sputtering target available from H.C. Starck Solutions is the Gen 5.5 molybdenum plate, with an expanded width of 1580 x 1950mm. H.C. Starck Solutions manufactures molybdenum sputtering targets and machined targets for Gen 1 to 8 sputtering equipment configurations.

H.C. Starck Solutions’ materials are recognized by key flat panel display manufacturers due to their high purity, uniform microstructure, density, consistency, high power density, low resistivity, and superior sputtering performance characteristics. With local support from more than 30 locations across the globe, the company helps customers to select the appropriate solution for all refractory metal applications:

H.C. Starck Solutions also produces sputtering alloys for use in TSP applications. Flexible and curved touch screens are the newest technology in HDTV, tablets, smart phones, and other mobile devices. H.C. Starck Solutions’ molybdenum-niobium (MoNb) targets are used in touch screens to sputter thin films for conducting, capping and barrier layers in these devices.

H.C. Starck Solutions supplies different compositions of single piece length tiles depending on the specific requirements of customers. Thin films made from MoW targets exhibit superior wet and dry etching characteristics. Flexible touch screen devices are the evolving technology in TSP application, requiring higher durability and performance.

With its sputtering target materials and rapid product development capabilities, H.C. Starck Solutions helps customers to achieve improved system performance and cost. H.C. Starck Solutions’ knowledge in thin film characterization and ESBD analysis of textures enables rapid development of these innovative alloys.

H.C. Starck Solutions employs a unique processing of refractory metals, including high temperature rolling, powder metallurgy processing, rotary forging and extrusion, for customized alloy development. The company’s innovative extrusion process manufactures a range of materials, sizes, lengths, and shapes for thin films and a multitude of other applications. Its extruded targets have higher relative density than Hot Isostatic Press (HIP) targets.

This information has been sourced, reviewed and adapted from materials provided by H.C. Starck Solutions.

For more information on this source, please visit H.C. Starck Solutions.

Please use one of the following formats to cite this article in your essay, paper or report:

H.C. Starck Solutions. (2023, April 21). Molybdenum-Based Sputtering Targets in Flat Panel Displays. AZoM. Retrieved on January 16, 2024 from https://www.azom.com/article.aspx?ArticleID=13925.

H.C. Starck Solutions. "Molybdenum-Based Sputtering Targets in Flat Panel Displays". AZoM. 16 January 2024. <https://www.azom.com/article.aspx?ArticleID=13925>.

H.C. Starck Solutions. "Molybdenum-Based Sputtering Targets in Flat Panel Displays". AZoM. https://www.azom.com/article.aspx?ArticleID=13925. (accessed January 16, 2024).

H.C. Starck Solutions. 2023. Molybdenum-Based Sputtering Targets in Flat Panel Displays. AZoM, viewed 16 January 2024, https://www.azom.com/article.aspx?ArticleID=13925.

Do you have a review, update or anything you would like to add to this article?

Andrea Steck, Martius Cobo, Bruno Chencarek

In this interview, join Bruker as they describe how to improve battery production and performance, through the entire value chain, with the help of NMR.

In this interview, Sara Speak, the Industrial and Environmental Product Application Specialist at Veolia Water Technologies & Solutions, talks to AZoMaterials about the current challenges the food and beverage industry (F7b) faces in water management.

Dr. Craig Johnson & Dr. Kate Vanderburgh

AZoMaterials speaks with Dr. Craig Johnson, Director of Research Core Facilities, and Dr. Kate Vanderburgh, Scanning Electron Microscope (SEM) and X-Ray Microscopy Manager, about the Materials Characterization Core (MCC) facility at Drexel University.

This product profile describes the features and applications of the PlasmaPro ASP by Oxford Instruments Plasma Technology.

This article describes the features and applications of the Optical precision micrometer - optoCONTROL2520.

Discover the SAVANNAH Raman module, the most compact OEM Raman module.

The global semiconductor market has entered an exciting period. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. Current trends will likely shape the future of the industry, which is set to continue to show

The primary distinction between graphene-based batteries and solid-state batteries lies in the composition of either electrode. Although the cathode is commonly changed, carbon allotropes can also be employed in fabricating anodes.

In recent years, the IoT is rapidly being introduced into almost all sectors, but it has particular importance in the EV industry.

AZoM.com - An AZoNetwork Site

Molybdenum Spray Wire Owned and operated by AZoNetwork, © 2000-2024