Concrete is the most commonly used construction material for key infrastructure and buildings, but pure concrete cannot meet the stringent demands of the construction industry. To improve its strength and durability, concrete is commonly reinforced with various materials.

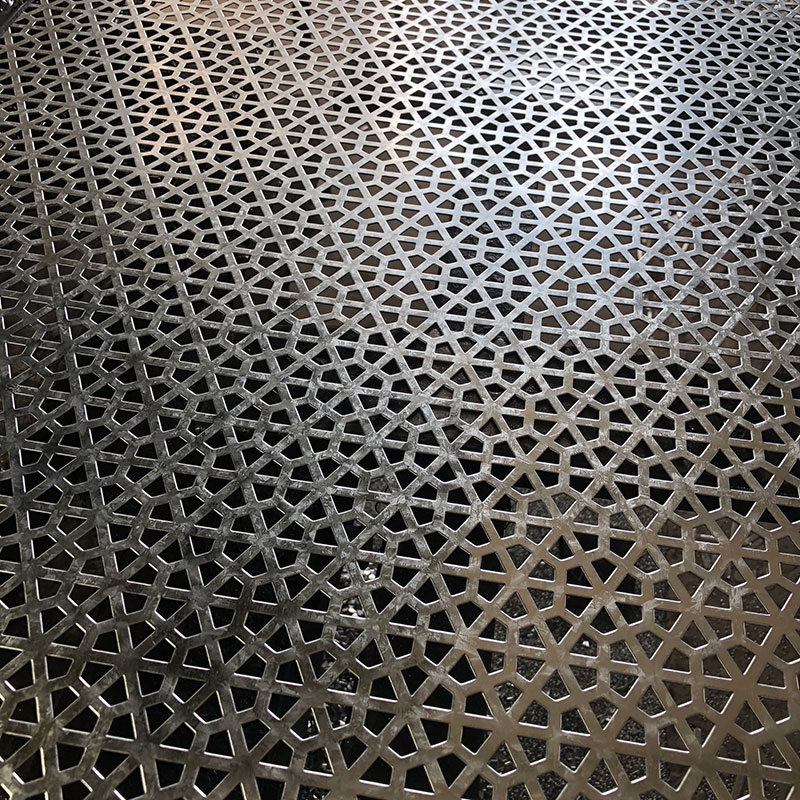

Image Credit: Htneim/Shutterstock.com Rib Lath

Concrete has a long history of use stretching back to ancient times, with precursor materials emerging in the Middle East around 1300 BC. The Romans made widespread use of concrete in structures such as The Pantheon and critical infrastructure such as bridges.

Today, concrete is used to construct everything from relatively small buildings to grand projects such as dams, bridges, tunnels, and airports. In order to ensure the safety of individuals, construction materials such as concrete must be extremely durable and able to withstand environmental stresses.

Reinforced concrete has almost double the strength of plain concrete. Not all concrete requires reinforcement, but to avoid structural failure, reinforced concrete is used in foundations, footings, slabs, and columns.

Reinforced concrete improves the durability and lifespan of structures due to concrete’s compressive strength and the tensile strength of the reinforcing element. Additionally, the thermal characteristics of concrete and steel, the most commonly used reinforcement material, are similar.

This similarity in thermal characteristics allows the concrete and reinforcing material (steel) to expand and contract at similar rates. Therefore, both materials function as a single unit, allowing reinforced concrete to withstand far higher environmental stresses, vibrations, and seismic events than plain concrete.

Since its invention in the late 19th century, reinforced concrete has revolutionized the construction industry. It can be said that reinforced concrete has built the modern world, as critical modern infrastructure projects would not be possible without it.

As previously mentioned, steel is the most commonly used reinforcing material. Two methods are used: steel rebar and mesh panels. These two techniques require different preparation methods.

Steel rebar is positioned at regular intervals across the concrete slab, both length- and widthways. Appropriate positioning tools and reinforcement ties ensure that the rebar grid is correctly positioned and will not move during the concrete pour.

Steel mesh is more appropriate for larger construction projects as it is more cost-effective and easier to install in large slabs. Mesh is placed across the slab with appropriate overlaps, ensuring equal reinforcement across all areas.

Whilst steel is the preferred material in reinforced concrete and ensures the safety and durability of concrete structures, there are some issues with its widespread manufacture and use. Steel is expensive, prone to rust, and its manufacture is a key contributor, along with concrete, to climate change in the construction industry.

To address the historical issues with the construction industry and help the sector achieve its net zero goals without compromising on the quality and durability of reinforced concrete structures, a number of alternative reinforcement materials have been developed in recent years.

Stainless steel reinforcement bars are low-carbon content materials with high corrosion resistance due to their chromium content. Chromium forms a layer on the surface of the stainless steel, which is responsible for the material’s superior corrosion resistance compared to conventional steel bars.

Stainless steel is considerably more expensive than standard steel bars, however. Their use must be considered carefully in construction projects to optimize the trade-off between performance and cost. Stainless steel bars are recommended for use in parking garages, jetties, moorings, retaining walls, piers, retaining walls, and columns.

Epoxy-coated rebars (also known as green bars) improve corrosion resistance and enhance the strength of reinforced concrete. More cost-effective than stainless steel (up to eight times cheaper), the quality of the coating is essential to ensure optimum corrosion resistance.

Fiber reinforcement polymers (FRPs) have emerged as viable alternatives to conventional steel rebars in recent years, moving increasingly from the lab to commercial applications. Fiber reinforcements improve the tensile strength and stiffness of concrete structures.

These green, low-carbon alternatives to steel incorporate fiber reinforcements, fillers, resins, and additives. A key benefit is their superior corrosion resistance compared to steel reinforcement. Furthermore, resins used in FRPs possess high compressive strength and bind the entire concrete mix, producing an extremely firm mass.

Several fibers have been investigated in studies for their use in FRPS, including fiberglass, carbon fiber, and aramid. Carbon fiber is, however, expensive, which limits its use in large-scale construction projects.

Another option that has been explored extensively in recent years is the use of recycled waste materials in FRPs. This satisfies the aims of the circular economy and helps to reduce the carbon footprint of new structures. Both natural and synthetic recycled fibers have been studied for their potential as reinforcement materials.

Reinforcing concrete is essential to ensure that buildings and infrastructure can satisfy rigorous demands and withstand environmental stresses. Steel is a commonly used material, but in recent years new and innovative materials have started to emerge which overcome historical issues with steel use.

As the world moves toward a low-carbon, circular economic model, the use of fiber-reinforced polymers and recycled materials will likely increase, presenting new opportunities for low-cost green construction and the reduction of greenhouse gas emissions without compromising quality, safety, and durability.

More from AZoBuild: Nanomaterials in Construction: Properties, Performance, and Applications

Meri, R et al. (2020) Recycled fibers in reinforced concrete: A systematic literature review Journal of Cleaner Production 248, 119207 [online] sciencedirect.com. Available at:

https://www.sciencedirect.com/science/article/abs/pii/S0959652619340776

The Constructor (website) How to Choose the Right Reinforcement Material? [online] theconstructor.org. Available at:

https://theconstructor.org/practical-guide/right-reinforcement-material/47922/

Britannica (website) Reinforced concrete [online] britannica.com. Available at:

https://www.britannica.com/technology/reinforced-concrete

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Reg Davey is a freelance copywriter and editor based in Nottingham in the United Kingdom. Writing for AZoNetwork represents the coming together of various interests and fields he has been interested and involved in over the years, including Microbiology, Biomedical Sciences, and Environmental Science.

Please use one of the following formats to cite this article in your essay, paper or report:

Davey, Reginald. (2023, April 12). Advances in Concrete Reinforcement Techniques. AZoBuild. Retrieved on January 29, 2024 from https://www.azobuild.com/article.aspx?ArticleID=8605.

Davey, Reginald. "Advances in Concrete Reinforcement Techniques". AZoBuild. 29 January 2024. <https://www.azobuild.com/article.aspx?ArticleID=8605>.

Davey, Reginald. "Advances in Concrete Reinforcement Techniques". AZoBuild. https://www.azobuild.com/article.aspx?ArticleID=8605. (accessed January 29, 2024).

Davey, Reginald. 2023. Advances in Concrete Reinforcement Techniques. AZoBuild, viewed 29 January 2024, https://www.azobuild.com/article.aspx?ArticleID=8605.

Do you have a review, update or anything you would like to add to this article?

In this interview, Murielle Goubard, the Global Sector Manager for Building Materials at Malvern Panalytical, talks to AzoBuild about sustainable challenges in the cement industry.

This International Women's Day, AZoBuild had the pleasure of speaking with Dr. Silke Langenberg from ETH Zurich about her impressive career and research.

AZoBuild talks with Stephen Ford, Director at Suscons and Founder of Street2Meet, about initiatives he is overseeing that look to provide sturdier, longer-lasting, and safer emergency shelter to those who need it.

This article will provide an overview of bioengineered building materials, discussing materials, products, and projects that have been made possible due to research in this area.

With an increase in the pressure to decarbonize the built environment and build more carbon-neutral buildings, the reduction of embodied carbon has become of great importance.

AZoBuild talks to Professors Noguchi and Maruyama about their research and development of Calcium Carbonate Concrete (CCC), a new material that has the potential to cause a sustainable revolution in the construction industry.

AZoBuild spoke to Lacol Architecture Cooperative about their La Borda Cooperative Housing project in Barcelona, Spain. This project has been shortlisted for the 2022 EU Prize for Contemporary Architecture - Mies van der Rohe award.

AZoBuild talked to Peris+Toral Arquitectes, finalists for the EU Mies van der Rohe award, about their work 85 Social Housing Units project.

With 2022 now underway, excitement has built following the announcement of the shortlisted architectural firms nominated for the EU Prize for Contemporary Architecture – Mies van der Rohe award.

AZoBuild.com - An AZoNetwork Site

Stainless Steel Welded Mesh Owned and operated by AZoNetwork, © 2000-2024