Roads directly affect the mine’s efficiency, operating costs, and safety. Their poor condition dramatically slows down the speed of the equipment and leads to the rapid wear of tires, breakdowns, and expensive repairs.

Since concrete roads are very time-consuming, labor-intensive, and expensive to build, the most widespread solution is roads with crushed stone. However, due to cyclic loads, the stone crumbles over time, pits and rutting are formed, maintenance is required, and the mine’s output decreases. Pe Composite Geomembrane

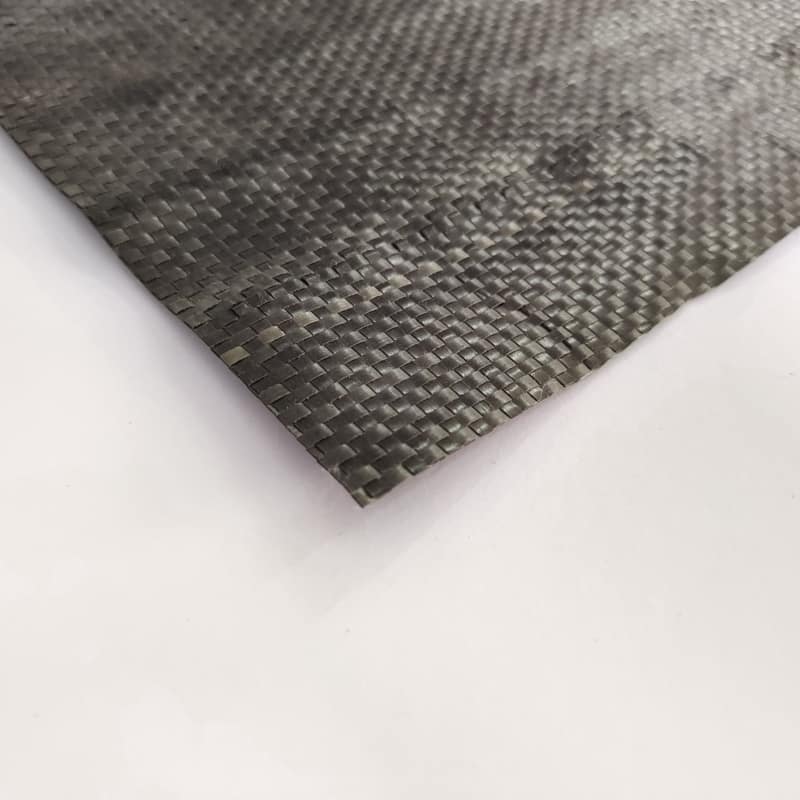

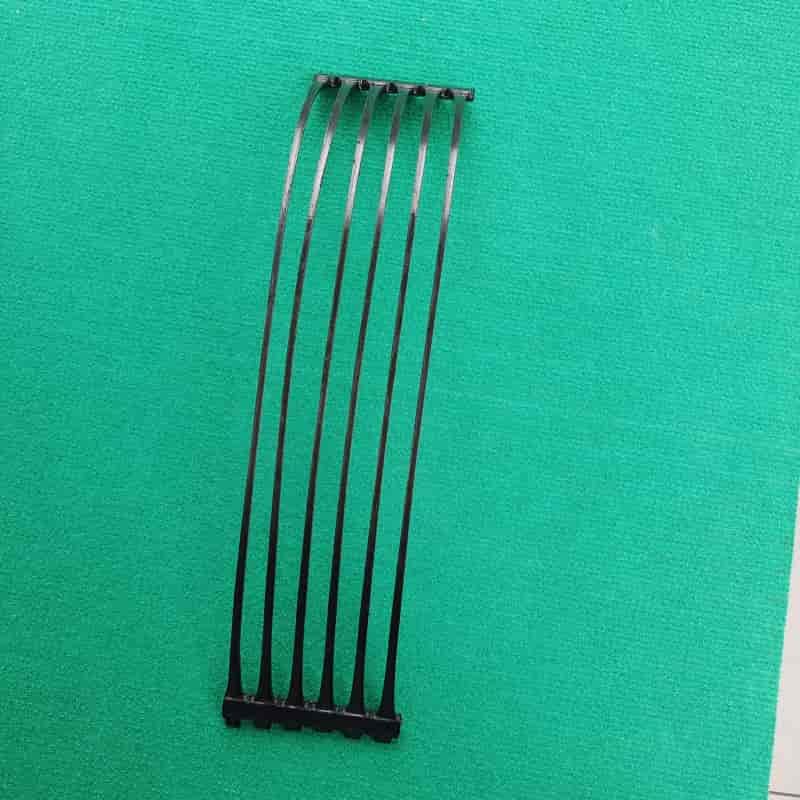

Geosynthetics manufacturer PRESTORUS found a solution to this problem and developed a new generation of geosynthetics, 3D reinforced geocell GEOCORD®. The patented technology includes the use of ultra-strong reinforcing threads in the polyethylene tape, which prevents plastic deformation.

The reinforced geocell does not stretch under constant loads and elevated temperatures, and maintains its geometric dimensions and shape. GEOCORD® is stronger and more reliable than standard 3D geocells and has an extended service life of up to 100 years.

The basic principle of the reinforced geocell is to redistribute the vertical load onto adjacent cells, which can significantly reduce the load on the underlying foundation. As a result, the road does not deform—on the contrary, it becomes more solid and even.

The wide range of GEOCORD® cell heights, sizes, and thickness allows you to choose the most optimal solution for construction under different axial loads.

The construction of a road with 3D geocells takes place in several stages. First, GEOCORD® is installed on the prepared base, and the cells are backfilled with crushed stone. Then the surface is leveled with a motor grader and compacted with a vibratory roller.

Simplicity and accessibility are the main advantages of 3D geocells. Since the installation does not require any additional equipment or tools, the labor intensity is significantly lower (by 63.5%).

The road design with 3D geocell GEOCORD® improves the operational qualities of open-pit roads, reducing the cost of their maintenance and repairs by up to 25%, since it contributes to increased strength and flatness of road pavement, improved adhesion and no spillage of the aggregate material.

Moreover, vehicle maintenance costs are reduced by up to 15% and fuel consumption is up to 7% lower, while the speed and productivity of the dump trucks increase by up to 3% and large-sized tire mileage is up to 18% higher.

Tunnel Drainage Network © All content copyright 2017 - 2023 VUKA Group, unless specified otherwise.