We use cookies to enhance your experience. By continuing to browse this site you agree to our use of cookies. More info.

Diamond film-coated tools (diamond-coated tools) are employed for difficult-to-machine materials like CFRP. In the production of diamond-coated tools, a pretreatment is needed to eliminate cobalt from the tool with a liquid to attain an even diamond film surface. Carbide Rotary File Blank

However, the team is still concerned regarding the environmental impact of liquid waste from liquid pretreatment (wet processing), and thus a process that does not require liquids (dry processing) is highly desirable.

A study group comprising master’s student Yoshinori Saiki, Assistant Professor Takahiro Bando, Lecturer Toru Harigai, Professor Hirofumi Takikawa from the Department of Electrical and Electronic Information Engineering at Toyohashi University of Technology, and others have disclosed the mechanism by which cobalt makes the diamond film surface non-uniform with the objective of developing a pretreatment that does not require wet processing.

Specifically, the team discovered that carbon filaments result in non-uniform formation in smooth, low-friction nanocrystalline diamond films and that carbon filaments’ inhibition is important. This research was done in association with OSG Corporation (a leading company in the Higashimikawa area) and Nagaoka University of Technology (which has powerful links with this university), which makes it a special research project for Toyohashi University of Technology.

Diamond film-coated tools (diamond-coated tools) are employed for difficult-to-machine materials. A typical example of difficult-to-machine materials is carbon fiber-reinforced plastic (CFRP), which is used as a light and rigid material to reduce the weight of aircraft and automobile bodies.

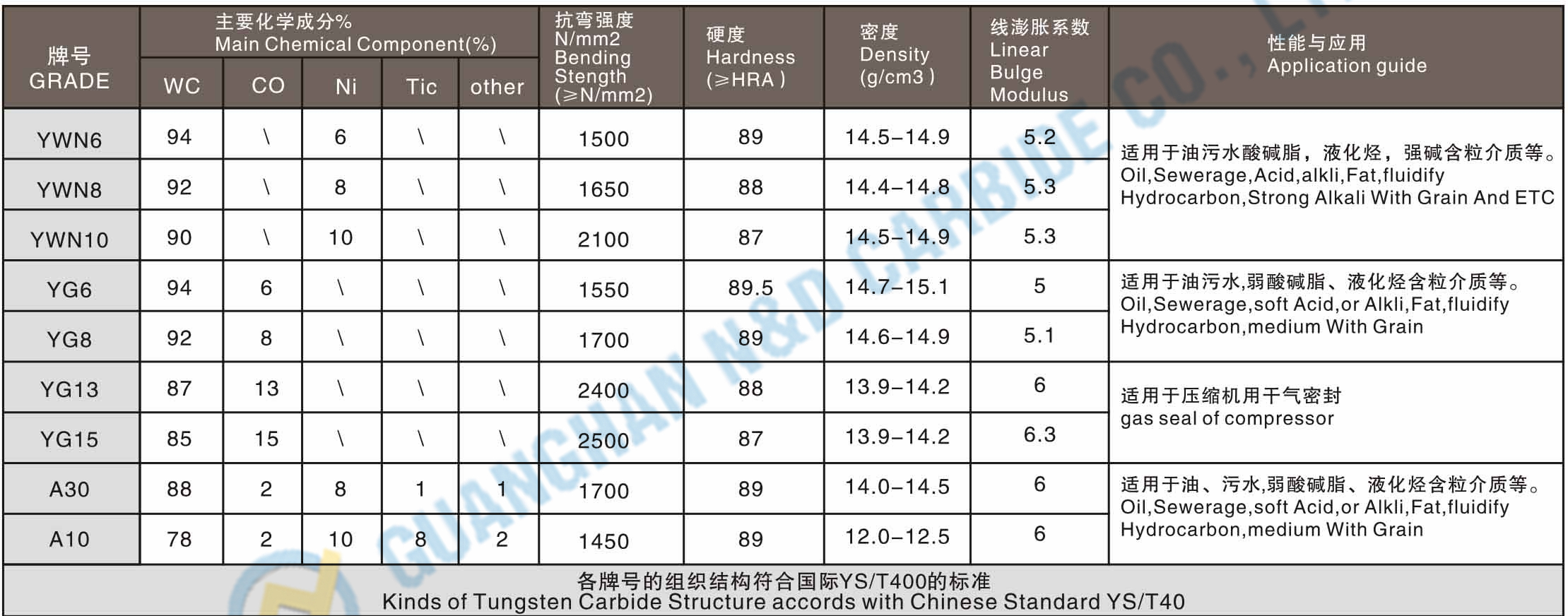

Cemented tungsten carbide with cobalt binder is normally used as a base material for tools used to deposit diamond films.

Hot filament chemical vapor deposition (HF-CVD) is also employed as the film deposition technique. When a diamond film is deposited on cemented tungsten carbide by HF-CVD, the quality of the diamond-coated tool deteriorates as the diamond film becomes non-uniform due to cobalt grains.

Thus, a pretreatment is needed to eliminate the cobalt on the cemented tungsten carbide with liquid.

Yet, there are concerns regarding the environmental impact of liquid waste from liquid treatment (wet processing), and thus there is a need to develop an approach that does not utilize liquids (dry processing).

In this research, the non-uniform formation mechanism for nanocrystalline diamonds was disclosed, as well as microcrystalline diamonds with a time-resolved view of the deposition process for microcrystalline diamonds and nanocrystalline diamonds.

Two kinds of diamond films are deposited on tools: nanocrystalline diamonds and microcrystalline diamonds.

Previous research has only outlined a mechanism for non-uniform formation for microcrystalline diamonds. However, there was no information available regarding nanocrystalline diamonds, which are smooth, have little friction, and are more suitable for tools.

In this study, the research team showcased a non-uniform formation mechanism for nanocrystalline diamonds as well as microcrystalline diamonds with a time-resolved observation of the deposition process for microcrystalline diamonds and nanocrystalline diamonds.

In nanocrystalline diamonds in particular, the carbon filaments were able to lift particles on the tungsten carbide substrate, making the substrate non-uniform, thereby causing non-uniform formation.

In this study, the researchers demonstrated the importance of inhibiting carbon filament growth in the initial stage of deposition to stop the non-uniform formation of nanocrystalline diamond films in dry processing.

In the future, the team hopes to create a deposition technique using HF-CVD in a high-temperature environment that can inhibit the growth of carbon filaments. Furthermore, after establishing a uniform formation process for nanocrystalline diamond films, the team plans on applying the process to real tools and investigate their machining performance.

Saiki, Y., et al. (2023). Sequential morphology of cobalt from cemented tungsten carbide in microcrystalline and nanocrystalline diamond films by HF-CVD. Diamond and Related Materials. doi.org/10.1016/j.diamond.2022.109643.

Source: https://www.tut.ac.jp/english/

Do you have a review, update or anything you would like to add to this news story?

Dr. Craig Johnson & Dr. Kate Vanderburgh

AZoMaterials speaks with Dr. Craig Johnson, Director of Research Core Facilities, and Dr. Kate Vanderburgh, Scanning Electron Microscope (SEM) and X-Ray Microscopy Manager, about the Materials Characterization Core (MCC) facility at Drexel University.

In this interview, News Medical speaks with John Weaver from Pfizer about the importance of process safety testing.

In this interview, AZoM speaks to Bruker Optics about the different ways IR light can be used in semiconductors.

Discover the SAVANNAH Raman module, the most compact OEM Raman module.

Specac’s Power Hydraulic Press Series are available in 8 Ton, 15 Ton and 25 Ton load configurations.

The SamplerSight Pharma from PMS is an easy-to-use software for batch sampling.

The global semiconductor market has entered an exciting period. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. Current trends will likely shape the future of the industry, which is set to continue to show

The primary distinction between graphene-based batteries and solid-state batteries lies in the composition of either electrode. Although the cathode is commonly changed, carbon allotropes can also be employed in fabricating anodes.

In recent years, the IoT is rapidly being introduced into almost all sectors, but it has particular importance in the EV industry.

AZoM.com - An AZoNetwork Site

Tungsten Carbide Wear Sleeve Owned and operated by AZoNetwork, © 2000-2023