Industrial Automation, Robotics and Industry 4.0

The encoders detect both the position and speed of the motors with absolute precision, even at 25,000 revolutions per minute hollow shaft encoder

The constant increase in the number of revolutions of vehicle drives forces engine test bench manufacturers to update the measurement technology of their systems.Hengstler's incremental encoders and absolute encoders are ideal for this purpose: They detect both the position and speed of the motors with absolute precision, even at 25,000 revolutions per minute.

With the rise of electromobility, the speeds of the drives are also increasingly increasing.The reason is simple: high-speed drives are more compact and lighter than conventional electric motors.This reduces the energy consumption of vehicles and increases their autonomy, an important selling point for the industry.

However, the higher speeds of the drives also require correspondingly powerful motor test benches.Conventional encoders can no longer measure the position of the drive shaft and the speed of the drive accurately enough above 12,000 rpm.

However, Hengstler encoders are up to the task.The ACURO AC58-I absolute encoder, for example, is ideal for use in engine test benches because it offers a high resolution of up to 29 bits (multiturn), as well as an integrated incremental encoder of up to 2,048 lines.

With its accuracy of 35'' and a repetition accuracy of 10'', the encoder is predestined for all applications where exact positioning with speed feedback is required.The ACURO AC58-I can be used on both the engine to be tested and the drive motor on the test stand.Thanks to its short length of just 50 mm, the ACURO AC58-I also adapts very well to the tight installation spaces of engine test benches.

The data transmission of the absolute encoder is optionally via an HTL or TTL incremental output.Via an SSI interface, the measured values can be sent to a controller for evaluation.For test bench applications with lower speeds, Hengstler offers the ICURO RI58D incremental encoder.This encoder has a measurement standard with 10,000 increments (direct reading) and can output up to 40,000 increments thanks to the True Read technology developed by Hengstler.At the customer's request, Hengstler also modifies its encoders to adapt them to their specific needs, and this starting from a batch size of 1.

Pere Garriga explains to us why absolute encoders give information encoded in Gray

Pere Garriga explains to us what it is and what are the main causes that generate tracking error in a servo motor.

Pere Garriga explains to us what encoders with Sine/Cosine outputs are and what they are used for.

The TBSN/TRSN series includes encoders for high functional safety requirements certified according to IEC61508, SIL3 and comply with ISO 26262, ASIL-D

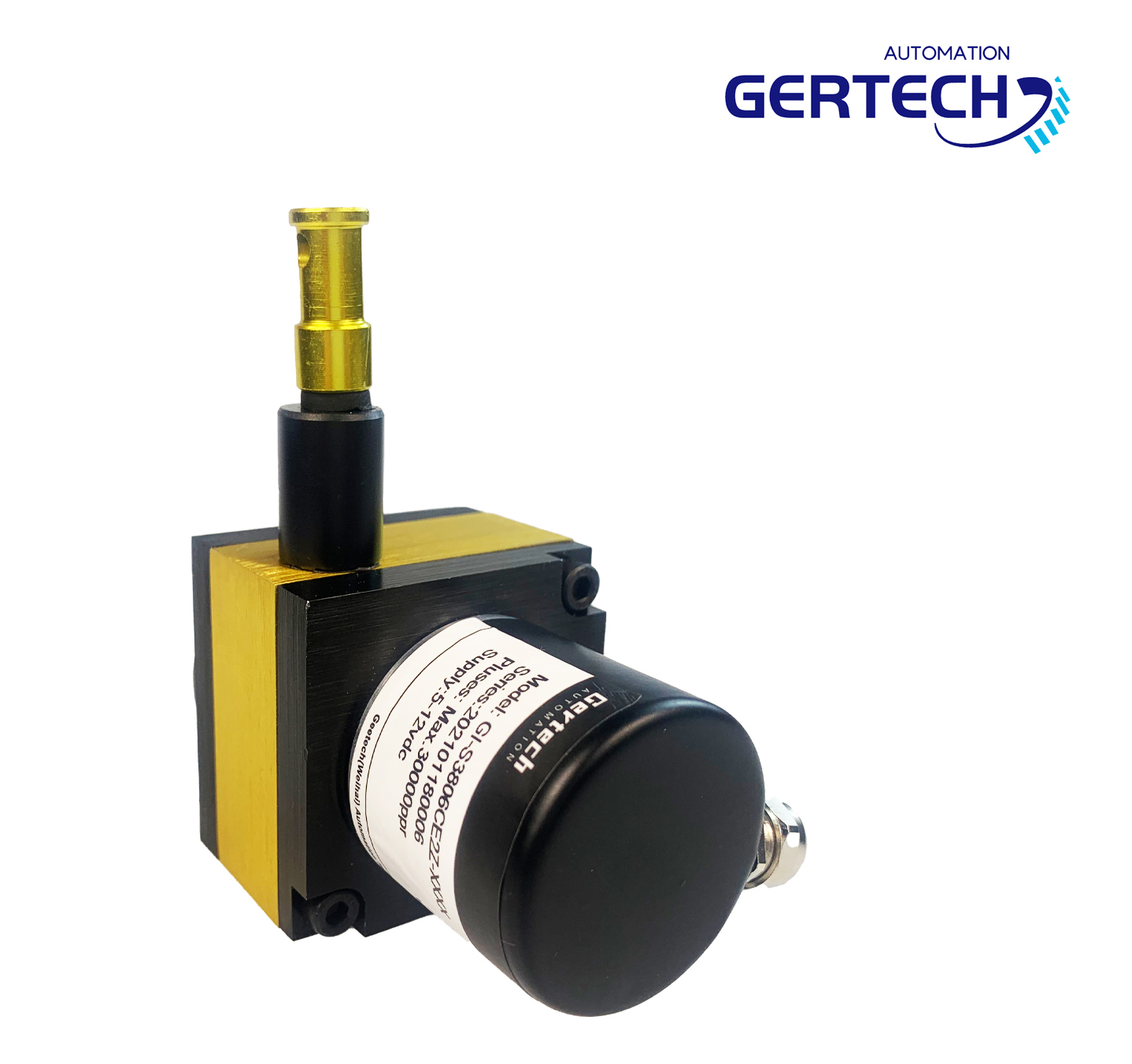

Wire Encoder Sensor ©2023 infoPLC.net Industrial Automation, Robotics and Industry 4.0