Arkansas Poly & Printing and Trex Company are celebrating the power of partnership. After joining forces just over a year ago, the producer of flexible consumer packaging has already contributed more than one million pounds of recycled plastic film packaging to Trex for use in the making of the company’s composite decking.

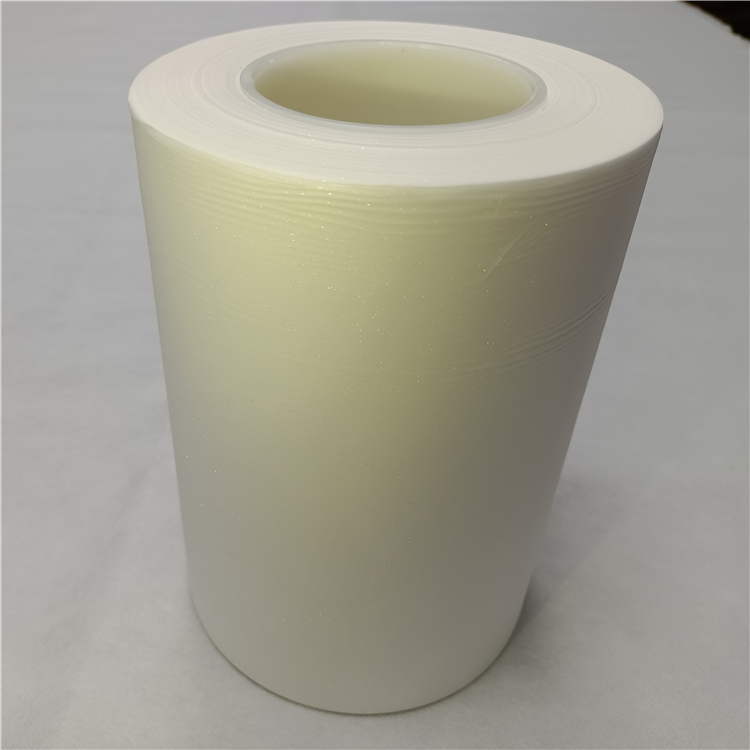

“This is an impressive milestone and a testament to the energy and commitment of the Arkansas Poly & Printing team,” said Zach Lauer, vice president of supply chain for Trex Company. “Commercial partners are essential to Trex’s sourcing efforts and we are excited to be working with an organization that shares our vision for driving the recycling of plastic films.” Tape

Founded on sustainable values, Trex makes its industry-leading composite decking using 95% recycled and reclaimed materials, including a mix of industrial wood scrap and polyethylene (PE) plastic film. Each year, the company diverts more than one billion pounds of these waste materials from winding up in landfills or waterways. The company operates manufacturing facilities in Virginia and Nevada and is in the process of building what will be its third U.S. production site located within the Port of Little Rock, Arkansas. The approximately $400 million campus will include buildings dedicated to decking and railing production, warehousing, reclaimed wood storage, and plastic film recycling and processing.

White Paper: Combat Industry Disruptors with Data

One of the largest recyclers of plastic film in North America, Trex partners with commercial and community organizations across the country to responsibly recycle plastic film through its NexTrex program. Arkansas Poly & Printing joined the NexTrex program in June 2022 and, over the past year, has collected and contributed more than one million pounds of postindustrial and postconsumer resin-based packaging products to be upcycled by Trex into beautiful, durable, eco-friendly outdoor living products.

“Our mission of making quality packaging with the least impact to the environment is in perfect alignment with Trex,” said Sarah Sparks Diebold, co-owner of Arkansas Poly & Printing. “This alliance further exhibits our commitment to sustainability within the packaging industry and adds value to our products by providing a tangible ‘next life’ for our resin-based packaging.”

Arkansas Poly & Printing is a vertically integrated Flexo-packaging manufacturer, which extrudes, prints and converts flexible film for industrial and consumer packaging purposes. The company has a focus on diverting plastic films from landfills by developing materials that are readily recyclable. In addition to recycling raw materials and printed film, the company encourages its customers to adopt recycling programs and offers resources to guide their efforts.

Join thousands of other lumber and building material industry leaders and keep up with the companies, people, products and issues shaping the industry.

Download this 55-page, in-depth study by LBM Journal of industry trends in sales force compensation and benefits. See how your organization stacks up.

LBM Journal is the leading media company serving lumberyards, building material distributors, wholesalers, manufacturers, and service providers.

Plastic Film Wrap Copyright © 2024 LBM Journal. All Rights Reserved.